Maximizing Boiler Efficiency: The Crucial Role of Water Quality

The boilers’ efficiency in residential environments, crucial for energy expenditure and ecological impact, mirrors a boiler’s capacity to transform fuel into heat. This performance, key to reducing energy expenses and minimizing environmental impact, is profoundly shaped by the quality of water used. Contaminants such as minerals, gases, and organic compounds in water lead to issues like scaling, corrosion, and foaming, which can hinder boiler efficiency. Thus, prioritizing and maintaining water quality is essential for achieving peak boiler performance.

Fundamentals of Boiler Operations

Contents

- 1 Fundamentals of Boiler Operations

- 2 Impact of Water Purity on Boiler Performance

- 3 Boiler Water Treatment Strategies

- 4 Advantages of Maintaining Optimal Water Quality in Boilers

- 5 FAQs on Boiler Efficiency and Water Quality

- 5.1 What Is “Boiler Efficiency”?

- 5.2 How Can I Tell if Poor Water Quality is Affecting My Boiler’s Efficiency?

- 5.3 Can Regular Tap Water Be Used in Boilers?

- 5.4 How Often Should Water Quality Be Checked in Boiler Systems?

- 5.5 What Are the Long-Term Implications of Neglecting Water Quality in a Boiler System?

- 5.6 Conclusion

- 6 Contact Miller Oil Company for All Your HVAC Requirements

Keep reading to explore the fundamentals of boiler operation.

Water’s Significance in Boiler Systems

In boiler systems, water plays a pivotal role as a medium for heat transfer, essential for disseminating the energy derived from fuel combustion for heating purposes or industrial operations. Specifically, in steam boilers, the water temperature is elevated to the point of vaporization, generating steam that is then utilized in many applications.

Essential Elements of a Boiler Setup

A boiler setup is comprised of multiple crucial components. The burner initiates fuel combustion in the combustion chamber, converting it into heat. This heat is subsequently conveyed to water through the heat exchanger. Additionally, the system encompasses various controls and safety mechanisms to ensure efficient and secure functioning. Moreover, the flue stack is responsible for expelling the by-products of combustion. Every component is vital to the system’s collective efficiency and effectiveness.

Impact of Water Purity on Boiler Performance

Water quality in boiler systems is a critical factor influencing their efficiency. These contaminants include:

- Minerals: Elements like calcium and magnesium, typically found in hard water, are common.

- Gases: Oxygen and carbon dioxide, among others, can seep into the system.

- Organic Compounds: These can enter the system from a variety of origins.

- Suspended Particles: These may originate from internal and external system sources.

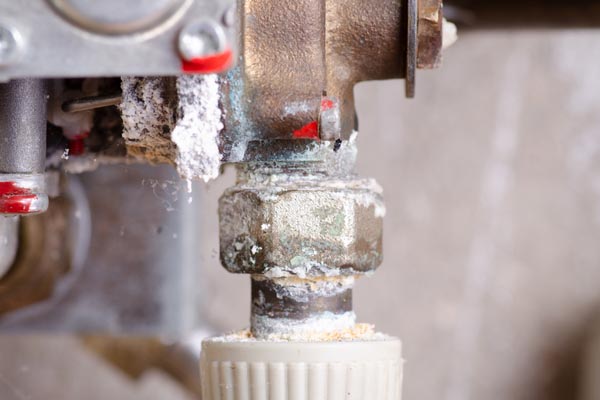

Formation of Scale and Its Consequences

Scale accumulation presents a significant challenge in boiler systems, resulting from the deposit of minerals such as calcium and magnesium. This phenomenon results in:

- Creation of Scale: This occurs when these minerals accumulate and solidify on the surfaces within the boiler.

- Impeded Heat Transfer: The presence of scale acts as a barrier, reducing the effectiveness of heat transfer.

- Risk of Tube Obstructions: The scale buildup can cause blockages in tubes, potentially leading to damage.

The Adverse Impact of Corrosion

Corrosion within boiler systems is a critical concern, originating from several sources, including oxygen infiltration and pH imbalances in the water. This corrosive process can compromise the integrity of boiler components, posing threats to the system’s efficiency and safety. Furthermore, problems associated with corrosion typically lead to diminished boiler efficiency, highlighting the necessity of timely intervention to mitigate these issues.

Foaming, Priming, and Carryover

Issues such as foaming, priming, and carryover, though less common, arise from elevated levels of impurities in the water and can significantly impair boiler efficiency. These problems often lead to suboptimal steam quality, diminishing the system’s efficiency. Moreover, complications like foaming and carryover can harm the equipment downstream of the boiler, necessitating additional maintenance and posing operational hurdles.

Boiler Water Treatment Strategies

Some effective strategies for boiler water treatment include:

Methods for Pre-Treatment

Implementing effective water treatment strategies is vital for upholding boiler efficiency, with pre-treatment methods being a key component. These methods include:

- Filtration Systems: Tailored to eradicate particulate substances and suspended particles in the water.

- Water Softening and Ion Exchange: These systems aim to lessen water hardness by extracting minerals such as calcium and magnesium.

- Deaeration and Oxygen Scavengers: Utilized for removing dissolved gases, especially oxygen, to prevent corrosive effects.

- pH Control and Alkalinity Enhancement: These treatments are essential for sustaining appropriate pH and alkalinity levels and averting issues like corrosion and scale buildup.

In-System Treatment Techniques

To further safeguard against losses in efficiency and damage, internal treatment techniques are applied directly within the boiler system. These techniques encompass:

- Scale Inhibitors: Specialized chemicals designed to avert scale buildup on internal boiler surfaces.

- Corrosion Inhibitors: Compounds that contribute to the protection of the boiler’s metallic surfaces from corrosive processes.

- Anti-Foaming Agents: These minimize foaming within the boiler, which can adversely affect steam quality and operational efficiency.

- Dispersing Agents: Employed to facilitate the dispersion of suspended particles, thus preventing the accumulation of sediments.

Ongoing Surveillance and Automated Regulation Systems

Continuous oversight and management of water quality are indispensable for the sustained efficiency and safety of boiler systems. This entails:

- The Necessity of Persistent Monitoring: Regular surveillance aids in the prompt identification and resolution of emerging water quality concerns.

- Technological Evolution in Managing Boiler Water Quality: Cutting-edge technological solutions offer accurate and automated water quality regulation. This technological progression has greatly enhanced the ability to sustain ideal water conditions, thereby boosting boiler systems’ overall efficiency and durability.

Advantages of Maintaining Optimal Water Quality in Boilers

Maintaining optimal water quality in boilers yields numerous essential benefits, influencing operational performance and safety.

Enhanced Efficiency and Economic Benefits

Superior water quality elevates boiler efficiency, reducing energy usage and considerable economic savings. This efficiency is attained by averting prevalent problems such as scaling and corrosion, which otherwise hinder the boiler’s capacity for effective heat transfer.

Prolonged Durability of Boiler Equipment

Utilizing clean water minimizes the likelihood of harmful scale accumulation and corrosion, consequently prolonging the service life of boiler components. This results in a less frequent need for replacements and repairs, significantly enhancing the overall longevity of the boiler system.

Minimized Maintenance Expenses and Operational Interruptions

With fewer water quality-related problems, boilers demand less regular maintenance and are less prone to malfunctions. This leads to a reduction in both the direct costs associated with maintenance and the disruptions caused by operational downtimes.

Improvements in Safety

Appropriate water treatment and diligent management significantly improve the safety aspects of boiler operations. Ensuring good water quality helps prevent problems resulting in leaks or explosions, thereby providing a safer operational environment in both residential and industrial contexts.

FAQs on Boiler Efficiency and Water Quality

Read some common FAQs on boiler efficiency:

What Is “Boiler Efficiency”?

Boiler efficiency refers to the effectiveness with which a boiler converts the energy contained in its fuel to usable heat. This efficiency level is usually quantified as a percentage, representing the proportion of the total energy in the fuel that is effectively transformed into heat.

How Can I Tell if Poor Water Quality is Affecting My Boiler’s Efficiency?

To ascertain if inferior water quality is impinging on your boiler’s efficiency, look for signs such as diminished heating capability, escalated fuel usage, and unusual noises or operational behaviors. These indicators often point toward problems like scaling, corrosion, or other water-related complications within the boiler.

Can Regular Tap Water Be Used in Boilers?

Using tap water in boilers is technically feasible but might not be the best choice. Tap water can contain various impurities, including minerals and chemicals, contributing to scaling and corrosion. These factors can adversely affect the boiler’s efficiency and reduce its operational lifespan.

How Often Should Water Quality Be Checked in Boiler Systems?

Monitoring the water quality in boiler systems routinely is advisable, ideally once a year. Such regular assessments are crucial for the early identification and remediation of any water-related issues that could potentially compromise the system’s performance.

What Are the Long-Term Implications of Neglecting Water Quality in a Boiler System?

Over time, ignoring the water quality in a boiler system can lead to decreased efficiency, heightened repair and maintenance expenses, and a reduced boiler lifespan. Furthermore, such negligence can pose significant safety risks, including the potential for leaks or system failures.

Conclusion

The critical importance of water quality in influencing boiler efficiency is paramount. Optimal water conditions are indispensable for sustaining high levels of efficiency, extending the lifespan of equipment, and guaranteeing safety. Emphasizing regular maintenance, diligent monitoring, and integrating proficient water treatment strategies is essential. Prioritizing these factors enables homeowners and facility managers to protect their boiler systems effectively, enhance performance, and circumvent expensive repairs, thus achieving both economic and operational efficiency.

Contact Miller Oil Company for All Your HVAC Requirements

When it comes to heating and cooling services in the Greater Enfield, Connecticut area, Miller Oil Company is the name you can rely on. Our team of certified technicians excels in HVAC tune-ups, repairs, installations, and replacements, ensuring your system operates at its best. Count on us for expert service delivered with knowledge and experience.

At Miller Oil Company, we provide competitive pricing and guarantee improved comfort, enhanced energy efficiency, and reduced home heating and cooling costs. Whether you require a repair or a new HVAC system, we’ll recommend the ideal solutions that align with your budget, all backed by our satisfaction guarantee. Contact Miller Oil Company today for a complimentary in-home estimate and experience top-notch service.

To schedule a service appointment, contact Miller Oil Company today. We also offer free, in-home estimates. Click the link to view our service area.

Related Articles: